Solvent Weld Waste Swept bends are used to create a 92.5 degree change of direction in a waste pipe system. They have a longer radius than knuckle bends and the 92.5 degree angle promotes a self-cleansing flow.

To make a solvent weld joint, first ensure that the outer wall of the pipe and the inner wall of the fitting are both clean and free from grit or swarf. Apply SC250 solvent cement to both surfaces. Push the pipe fully into the fitting and give it a twist to ensure that full contact has been made. Clean off any excess solvent with a damp cloth and leave for 5 minutes to set. The installation should be left for 12 hours before testing.

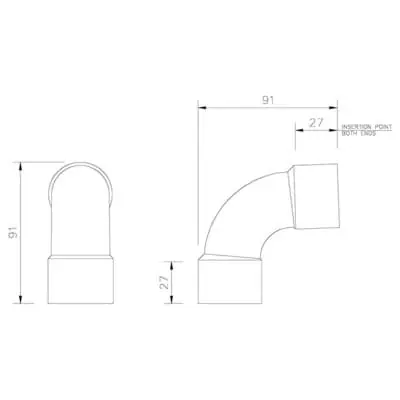

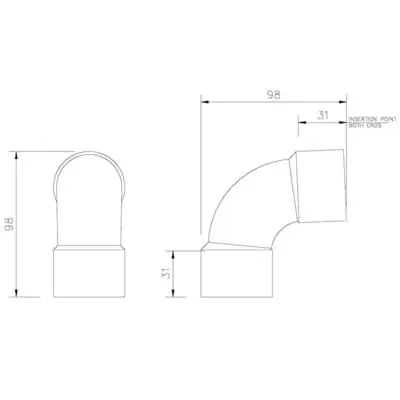

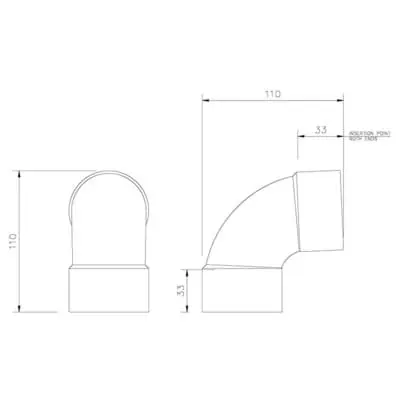

This fitting is available in 32mm, 40mm and 50mm size options.

Our solvent weld waste is manufactured in the UK to BS EN 1455 and is kitemarked.

Key Features:

- Light weight yet strong

- Cost effective

- Extensive range of fittings to meet most installation requirements

- Made in ABS

- Requires solvent welding