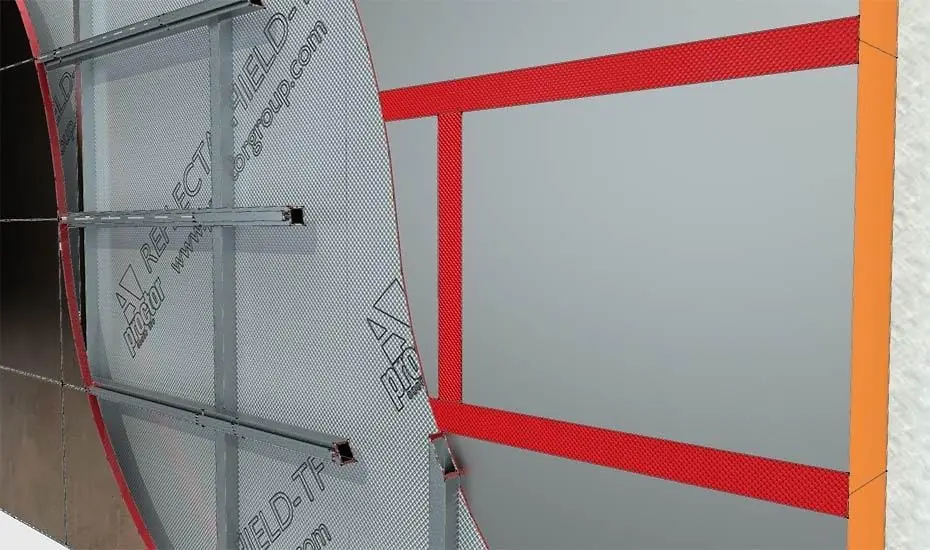

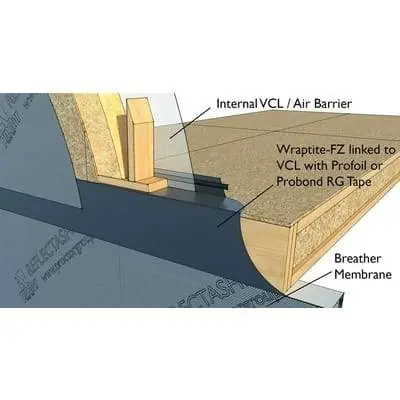

A useful way of stopping unnecessary air leakage around openings and overlaps is to use Wraptite Tape, an airtight, tear resistant tape with high vapour permeability for internal and external applications.

It fully bonds to all standard substrates, suppressing air leakage around joints, openings and penetrations. It is also suitable for permanent airtight sealing of membrane overlaps.

Composition

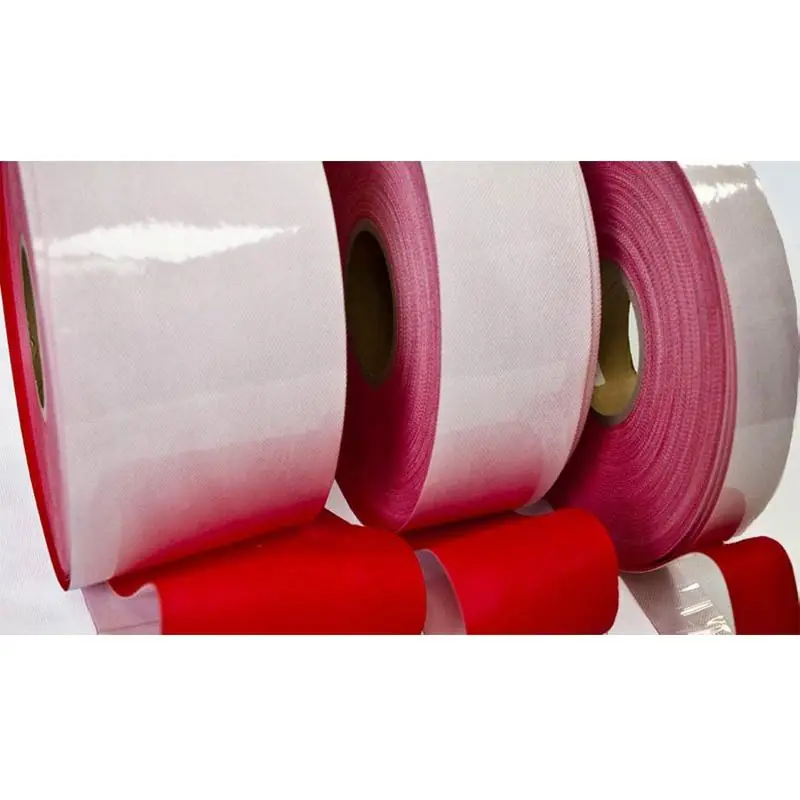

Wraptite Tape consists of a triple layer polypropylene micro-porous film laminate, with a proprietary acrylic moisture vapour permeable adhesive and silicone-coated PET release liner. Wraptite Tape is also available as a split release liner

for ease of installation.

Drying Capacity

Wraptite Tape’s high vapour permeability allows damp sheathing to dry quickly and moisture vapour to escape. This ensures good indoor air quality and reduces the likelihood of mould, mildew, condensation, timber distortion and metal corrosion.

Key Benefits

• Airtight and vapour permeable

• Resilient composition, which resists punctures and tears during construction

• Flexibility, facilitating ease of application and detailing

• Wide operating temperature range (-40°C to +100°C)

• Can be left exposed for up to 90 days (North America) or 120 days (UK) during construction*

• No primer required

• Suitable for sealing insulation boards

• Free from Volatile Organic Compounds

Multiple Substrate Compatibility

• Exterior Gypsum Sheathing

• Aluminium

• Rigid insulation

• Cast-in-place concrete

• Pre-painted steel

• Galvanized metal

• OSB

• Rigid vinyl

• Precast concrete

• Steel

• Concrete block

• Plywood

(Additional substrate compatibility available upon request.)

Vapour Permeability

With an Sd rating of 0.039, Wraptite Tape provides a highly vapour permeable, but fully airtight performance for multiple applications and conditions.

These crucial characteristics allow moisture vapour to escape the structure easily whilst maintaining the integrity of the building envelope.

Installation Instructions

Wraptite Tape should be applied to all vertical and horizontal joints between insulation boards

• Ensure surface of insulation boards are clean and free of dirt and grease prior to application

• Pull and fold back release liner from end of tape, line up tape over joint and apply pressure for initial tack

• Ensuring the tape follows the line of the joint, continue to pull release liner while taping over joint

• Apply pressure to tape using a hand roller or successful adhesion